The load-bearing

structures

Wood is a combustible material, but also a bad heat-conductor. That’s why it is used for the creation of load-bearing structures not only because it is aesthetically fascinating and cheap, but also, above all, because in case of fire it has a great mechanical resistance, that can be useful to increase the necessary time, in order to rescue all the people inside the room.

STEEL-CONCRETE

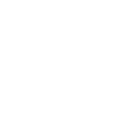

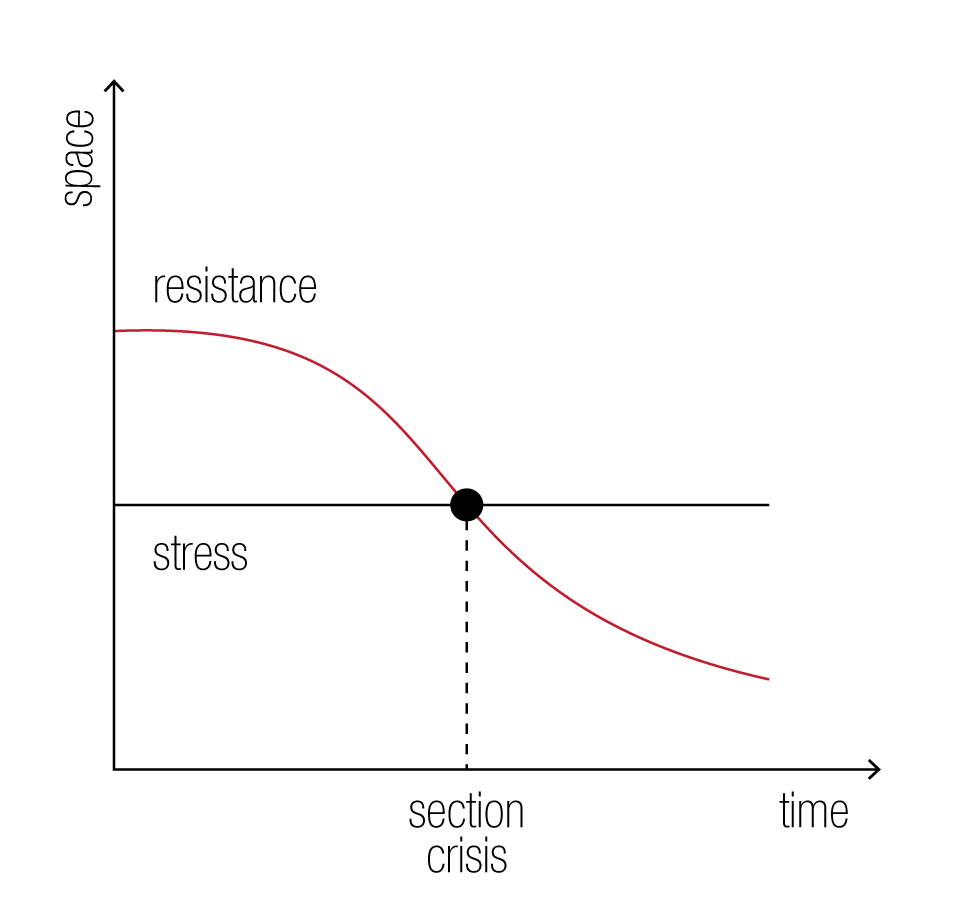

The temperature increase reduces the material mechanical features, but leaves unchanged the geometry of the section

WOOD

The temperature increase leaves (almost) unchanged the material mechanical features, but reduces the geometry of the section

The chart shows the trend of the two components, wood and steel/concrete in front of a potential fire.

WOOD

The fire penetrates with an average speed of 0,7-0,9 mm/minute, creating a burned carbonic layer, that limits the flame development. The temperature, inside the wooden beam of only few centimetres, is only 40°C against 1000°C outside. The fire and the heat don’t change the mechanical resistance. The collapse occurs when the combustion reduces the geometry of the left cross section, so that it can be no more a load-bearing structure. The duration is proportional to its own thickness, so that it is possible to support high loads and resistances only with an oversized beam, without a treatment with fire-retardant or intumescent coatings, plasters or silicon calcium slabs.

STEEL

Steel is considered as an incombustible material and this is true, but steel is also a good heat conductor. If submitted to a drastic increase of temperature, as in case of fire, the steel loses its stability.

After only 5 minutes of exposure to fire, the steel reaches more or less 500°C. This represents the critical temperature for this material. After 10 minutes of fire the steel construction becomes enervated and collapses on itself like a house of cards. Steel expands about 0,012 mm per every meter of length and temperature degree. In case of a temperature of 500°C, that means a lengthening of 6mm per meter. It is compulsory the use of intumescent coatings or other types of protection.

CONCRETE

Because of its composition, also reinforced concrete or concrete is classified as a not combustible building material. The capacity to be a heat conductor of concrete is 2,1 W/mK, against 60 W/mK of steel; this is an important factor to be considered, when there are components such as reinforced concrete and, in particular, pre-cast concrete.

The calcareous aggregates don’t lose in mechanical resistance, if not above 750°C, when the heat decay of limestone in lime and carbon dioxide starts.

The problem is the inner content of steel and the main role is the heat protection of concrete cover. In fact, in structures with reinforced concrete, the high temperature has a relevant importance towards steel, that above 500°C loses the major part of its features.

These weaknesses become “fast tracks” for the heat flow, provoking a localised temperature increase, that can exceed 500°C in a very short time. Even in this case the fire trend is similar to a steel beam, that’s why it is compulsory the use of intumescent coatings or other types of protection.